In today's planet of increasingly strong and compact electronics, productive thermal administration is not a luxury – it is a requirement. Overheating can lead to lessened functionality, program instability, as well as catastrophic failure. That's in which custom made heat sinks are available. not like off-the-shelf answers, personalized types are tailor-made to the particular demands of one's software, ensuring ideal heat dissipation and trustworthy operation. This information will examine the important role of tailor made warmth sinks, significantly Extruded Profiles Heatsink, in many industries and supply insights into planning and balancing Expense with efficiency.

Table of contents:

critical Industries That take advantage of customized Heat Sink remedies

the best way to style and design a tailor made Heat Sink for ideal Thermal administration

Value vs. functionality: Balancing customized warmth Sink specs

critical Industries That gain from customized warmth Sink methods

various industries depend upon custom made warmth sinks to maintain the performance and longevity in their Digital components. The telecommunications sector, with its dense networking products, Added benefits considerably from tailor-made thermal answers that avert overheating and ensure uninterrupted services. likewise, the power electronics industry, coping with substantial-voltage and superior-current programs, necessitates strong warmth sinks to handle the powerful warmth generated by electric power transistors click here and rectifiers. On top of that, the aerospace and defense industries, exactly where reliability underneath Excessive problems is paramount, rely upon personalized patterns to resist harsh environments and maintain crucial system functionality. Even in clinical equipment, the place precision and safety are crucial, custom heat sinks Participate in a significant job in protecting against overheating and guaranteeing precise diagnoses and remedies.

the way to layout a custom made warmth Sink for ideal Thermal administration

planning an efficient custom made heat sink consists of thorough thing to consider of various things. 1st, knowledge the warmth supply and its thermal qualities is essential. This consists of pinpointing the power dissipation, temperature boundaries, and mounting demands. Next, choosing the right material is critical. Aluminum is a well-liked choice on account of its superb thermal conductivity, light-weight, and cost-effectiveness, creating Extruded Profiles Heatsink a common solution. Copper gives remarkable thermal efficiency but is heavier and costlier. The geometry of the warmth sink is also critical. Fin density, fin peak, and foundation thickness all effects the warmth sink's capacity to dissipate warmth. Computational Fluid Dynamics (CFD) simulations may be used to improve the design and forecast thermal effectiveness just before physical prototypes are created. thinking of airflow and ventilation in the enclosure is usually essential, as correct airflow improves the heat sink's efficiency.

Price tag vs. functionality: Balancing personalized Heat Sink Specifications

even though maximizing thermal effectiveness can be a Principal goal, cost is likewise a major thing to consider when coming up with personalized heat sinks. greater-overall performance resources like copper will enhance the In general cost compared to aluminum. likewise, intricate geometries that involve intricate machining or specialized producing processes can even generate up expenses. picking out the ideal production system, for instance extrusion for Extruded Profiles Heatsink, can considerably impression Charge-efficiency. It's important to diligently Consider the thermal demands of your application and establish areas wherever overall performance might be balanced with Value savings. one example is, optimizing fin density or deciding on a far more Charge-effective alloy can typically offer a very good stability involving thermal efficiency and spending plan. Sourcing your custom made heat sinks from reputable companies who offer you style and design support and worth engineering can further more help in acquiring the exceptional Value-overall performance ratio. Renxin Precision, for example, features A variety of custom made warmth sink answers and can offer qualified guidance on optimizing your design for equally effectiveness and cost.

In conclusion, customized warmth sinks are important elements for guaranteeing the trustworthiness and effectiveness of Digital devices in an array of industries. By knowing The important thing design issues and carefully balancing Price with effectiveness, you are able to develop a custom made thermal Resolution that fulfills the specific needs of the software. Really don't wait to discover the main advantages of Extruded Profiles Heatsink and consult with experienced manufacturers like Renxin Precision to locate the best Remedy for your personal thermal management problems. get started optimizing your thermal overall performance now!

Judd Nelson Then & Now!

Judd Nelson Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Danny Pintauro Then & Now!

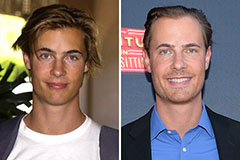

Danny Pintauro Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now!